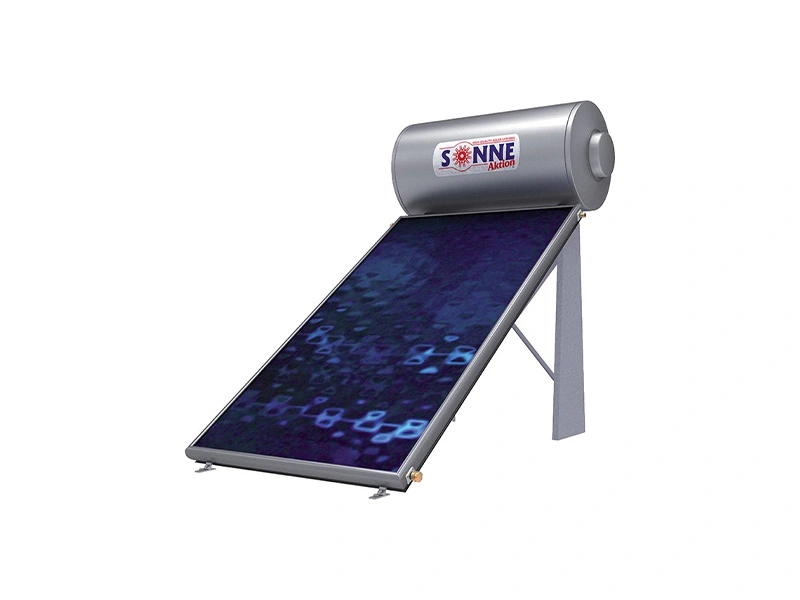

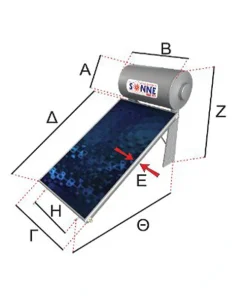

SOLAR HEATER SONNE GLASS 160Lit / 2.4m2 PHAETHON DUAL ENERGY

1.125,00 € Original price was: 1.125,00 €.860,00 €Current price is: 860,00 €.

With the technological superiority of 40 years of experience in manufacturing solar water heaters of high quality construction, performance and modern design, SONNE manufactures domestic water heaters with copper, glass and galvanized boiler type to meet the needs of hot water for both domestic and professional applications

3 in stock

SKU: VE-N4OCU453

Categories: DOUBLE ENERGY SOLAR WATER HEATERS, SOLAR - BOILER, SOLAR WATER HEATERS

Technical characteristics of PHAETHON solar panels

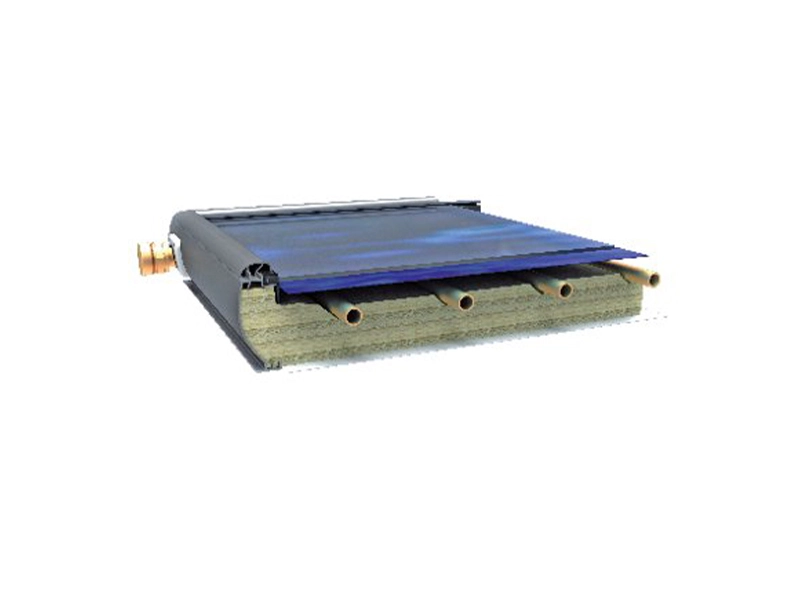

- Copper & aluminum are the materials used, i.e. non-corrosive materials, which ensure a lifetime of many decades. There are no steel parts to corrode

- Frame made of heavy-duty oval profile aluminum, highly aesthetic, advanced design, with internal corner die-cast aluminum screw corner joints that ensure the perfect fit & tightness of the frame parts & the great robustness of the collector.

- Selective surface absorber made of 4 mm thick aluminum sheets with a special coating of titanium oxides. The coating is made by a special vacuum treatment in Germany. The solar radiation absorption surface is in perfect fit on the copper hydroskeleton with welding in automatic LASER machines for direct transmission of heat to the thermal liquid. This ensures a very high absorption coefficient α>95% & a very low emissivity coefficient ε<5%, which contribute to the maximum thermal efficiency of the collector.

- Aluminum foil collector back ensures complete tightness against the frame without rivets.

- Absorber hydroskeleton made of copper tubes Φ8 & Φ22 mm

- 4 mm thick tempered safety glass with high permeability τ>0.94.

- Thermal insulation from fiberglass density d=30kg/m3 both on the back and on the sides of the collector.

- Oval rubber gasket of special design adapted to the copper connection pipes of the collector to prevent thermal bridging between the frame and copper pipes due to thermal expansion.

Technical characteristics of ATLAS solar panels

- Copper & aluminum are the materials used, i.e. non-corrosive materials, which ensure a lifetime of many decades. There are no steel parts to corrode

- Frame made of aluminum profiles, of high aesthetics, with external corner joints that ensure the excellent fit & tightness of the parts of the frame & the great robustness of the whole construction.

- Selective surface absorber made of 4 mm thick aluminum sheets with a special coating of titanium oxides. The coating is made by a special vacuum treatment in Germany. The solar radiation absorption surface is in perfect fit on the copper hydroskeleton with welding in automatic LASER machines for direct transmission of heat to the thermal liquid. This ensures a very high absorption coefficient α>95% & a very low emissivity coefficient ε<5%, which contribute to the maximum thermal efficiency of the collector.

- Aluminum foil collector back ensures complete tightness against the frame without rivets.

- 4 mm thick tempered safety glass of high permeability τ>0.94 with absolute sealing against the plasio.

- Thermal insulation from fiberglass density d=30kg/m3 on the back of the collector (back).

- Oval rubber gasket of special design adapted to the copper connection pipes of the collector to prevent thermal bridging between frame and copper pipes due to thermal expansions.

TΕΧΝΙΚΑ ΧΑΡΑΚΤΗΡΙΣΤΙΚΑ GLASS ΘΕΡΜΟΔΟΧΕΙΟΥ

Θερμοδοχείο: Από ευρωπαϊκό χαλυβδοελασμα πάχους 2,5mm με ειδική επίστρωση σμάλτου για πολύ μεγάλη διάρκεια ζωής

Μανδύας: Από ευρωπαϊκό χαλυβδοελασμα πάχους 1,5mm

Μόνωση: Διογκωμένη πολυουρεθάνη υψηλής πυκνότητας (50 kgr/m3) πάχους 60 mm

Θερμική αγωγιμότητα μόνωσης: 0,023 W/mK

Ράβδος ανοδικής προστασίας

Εξωτερικό περίβλημα: σε τέσσερις τύπους ανάλογα με τις ανάγκες σας (γκρι-inox-λευκό-κεραμιδί)

Πλευρικά καπάκια: Ειδικά σχεδιασμένα και διαμορφωμένα πρεσαριστά- κουμπωτά καπάκια, χωρίς βοηθητική συγκράτηση από πριτσίνια

Ηλεκτρική αντίσταση: ισχύος ανάλογα με τους κανονισμούς της χώρας προορισμού με θερμοστάτη μονοπολικού έλεγχου και διπολικής προστασίας

Υποδοχέας για το στέλεχος του θερμοστάτη

ΟΡΙΣΜΟΣ ΚΑΙ ΙΔΙΟΤΗΤΕΣ ΕΠΙΣΜΑΛΤΩΣΗΣ

ΤΙ ΕΙΝΑΙ ΕΠΙΣΜΑΛΤΩΣΗ

Επισμάλτωση είναι η ειδική γυάλινη επιφάνεια που δημιουργείται από την τήξη και ένωση του σμάλτου επάνω σε χαλύβδινη επιφάνεια.

Το σμάλτο - που είναι μίγμα ανόργανων πυριτικών αλάτων - είναι εντελώς υγιεινό και οικολογικό, αφού δεν περιέχει επικίνδυνες χημικές ουσίες, είναι υδατοδιαλυτό και ψήνεται σε υψηλές θερμοκρασίες (>850°C).

Η εφαρμογή του δίνει άριστη αντισκωρική προστασία και αντοχή σε απότομες μεταβολές θερμοκρασίας (θερμοσόκ) και δίνει την οικονομικότερη λύση για προστασία σε boilers και ηλεκτρικές κουζίνες.

ΙΔΙΟΤΗΤΕΣ ΕΠΙΣΜΑΛΤΩΣΗΣ

Προστασία από κάθε μορφής οξείδωση (γυάλινη επίστρωση)-αντοχή σε οποιεσδήποτε καιρικές συνθήκες.

Απόλυτα ασφαλής για τη δημόσια υγεία-εκπλήρωση των κανόνων υγιεινής- δεν επιτρέπει την ανάπτυξη των βακτηρίων

Αντοχή σε οξέα, στα graffiti και στην ηλιακή ακτινοβολία.

Αντοχή σε απότομες μεταβολές θερμοκρασίας (-60°C έως +450°C).

Εύκολη στον καθαρισμό-δυνατότητα χρωματισμών.

Άκαυστη- δεν έλκει τη σκόνη.

Ηλεκτρικά ουδέτερος συνδυασμός σμάλτου-λαμαρίνας.

Κατάλληλη για οποιαδήποτε ποιότητα νερού (ακόμα και θαλασσινό).

Ανακυκλώσιμο-φιλικό προς το περιβάλλον.

Μακροπρόθεσμη σιγουριά και ασφάλεια.

Οικονομικότερη από κάθε άλλη λύση.

Related products

-24%

DOUBLE ENERGY SOLAR WATER HEATERS

SONNE GLASS 120Lit / 1.7m2 DOUBLE ENERGY SOLAR HEATING SYSTEM

SOLAR - BOILER

1.373,00 €

-24%

SOLAR - BOILER

DOUBLE ENERGY SOLAR WATER HEATERS

ΗΛΙΑΚΟΣ ΘΕΡΜΟΣΙΦΩΝΑΣ CALPAK MARK 5 160Lit / 2.1m2 ΔΙΠΛΗΣ ΕΝΕΡΓΕΙΑΣ

1.131,00 €

Ελληνικά

Ελληνικά